New energy power battery

Detection of coating thickness of electrode film of lithium battery

Lithium battery electrode coating thickness measurement

1.Suitable products: coated cathode pole pieces, anode pole pieces, copper foil, aluminium foil

2. Suitable pole piece type: positive pole piece, negative pole piece

3. suitable for measuring types: continuous coated cold rolled, gap coated cold rolled, strip coated cold rolled

4. Application areas

This includes measuring the thickness of various lithium battery electrode sheet dressings (and also detecting the surface density of the measured material), cold rolled strip, steel sheet, aluminium sheet, aluminium foil, copper strip, copper foil, converter thin steel strip, wood sheet, medium thickness board, food, precision devices, all kinds of calendered rubber sheet, rubber film, rubber tyre, plastic sheet, transparent film, cloth and other transparent and non-transparent flexible sheet thickness, in-line, dynamic, non-contact, high-precision real-time measurement and control in the production process

Thickness of cell foam approx. 0.56 MM, thickness of intermediate pressing part 0.14 MM, thickness of coating part approx. 0.60 MM. speed of material movement 2-4 m/min.

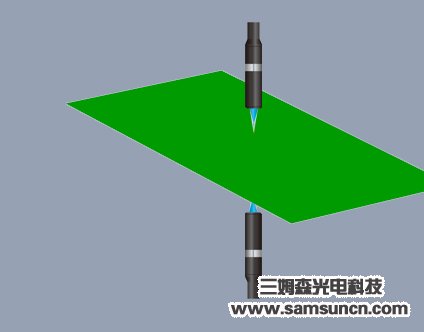

Measuring system device This system is used to detect the thickness variation of the lithium-ion battery positive and negative electrode slurry coating on aluminium and copper foil in real time online, calculate the corresponding variation amount of the knife gap and roll speed ratio of the scraper through the host machine, and feed back to the transfer coating machine to adjust the weight or thickness of the coating layer in real time, so as to maintain the consistency of the product.

The high precision laser in-line thickness measurement system has been applied to a number of battery plate coating machines, showing that the thickness gauge is extremely easy to use, stable and reliable, with stable measurement data and a measurement accuracy of ±0.5μm. The product will bring considerable indirect economic benefits to the company by reducing the consumption of raw materials and significantly reducing the scrap rate. Compared to existing conventional measurement methods, this method is environmentally friendly