Electronic components

Measurement of height of solder ball by spectral confocal method

In general, when checking the solder quality of BGA solder balls, if the shortcoming is bridging/short-circuiting, it can usually be checked with X-Ray equipment; however, it is more complicated to check if the solder balls are empty or broken.

There are basically four ways to check the solderability of a BGA: using spectral confocal sensor measurements, using X-Ray, penetrant red stain testing and slicing. In any case, when you want to analyse the solderability of a BGA it is advisable to use the spectral confocal sensor measurement method first to see if any problems can be identified, as this is after all a non-destructive inspection and only if the spectral confocal sensor measurement method or X-Ray fails to identify the problem should you proceed with the latter two destructive methods.

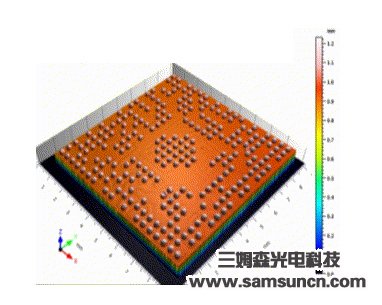

BGA tin ball height measurement using a spectral confocal sensor

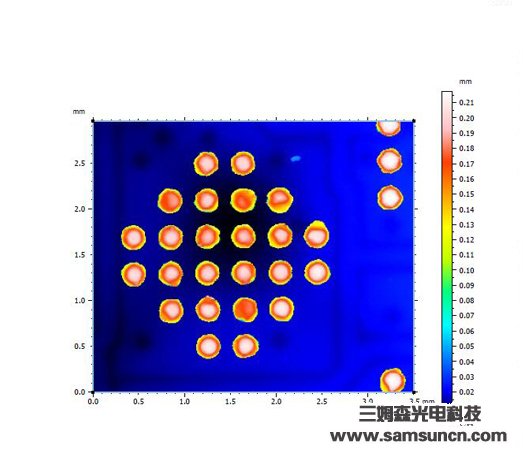

BGA tin ball height 2D plan view

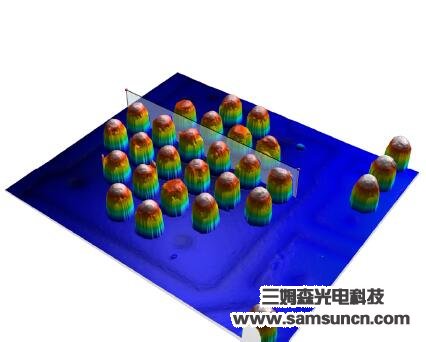

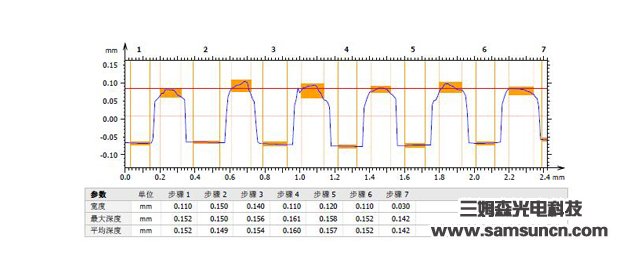

Extraction of local contours for analysis

Tin ball height values