Standard Equipment

3C consumer headset structural component product testing

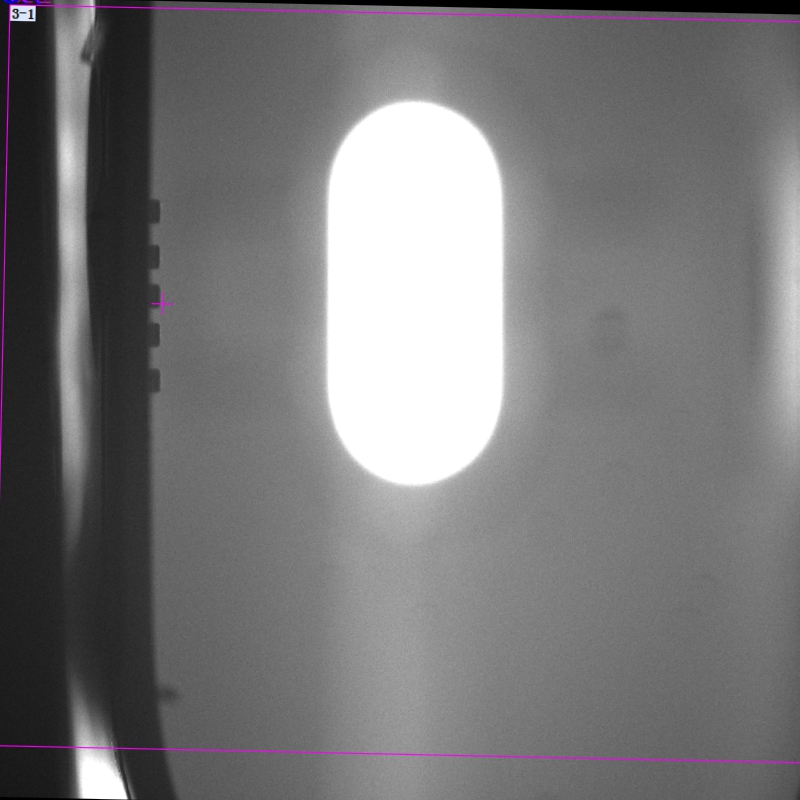

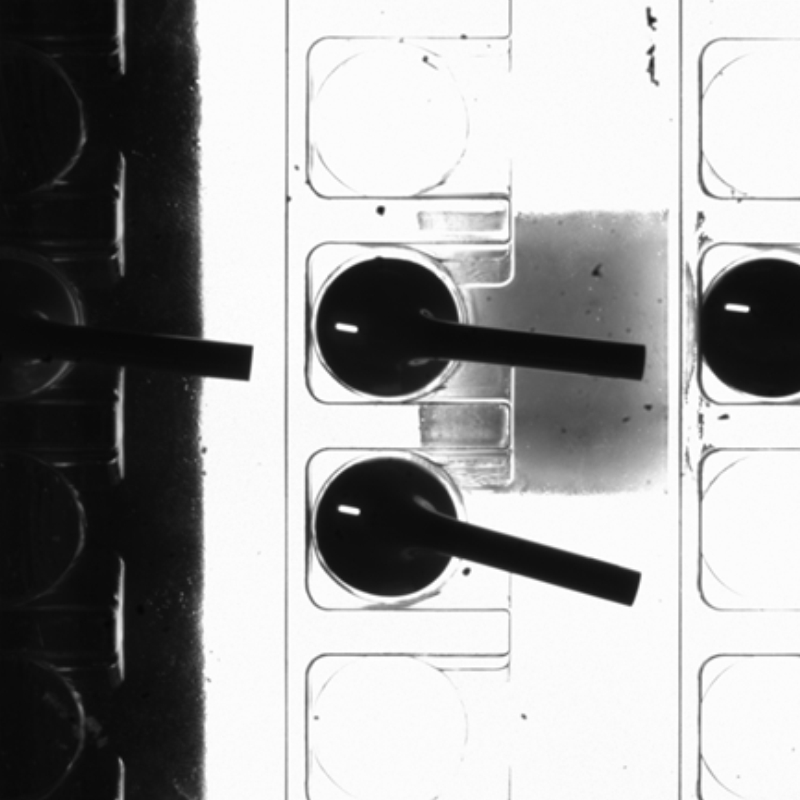

- CCD vision inspection, laser measurement, confocal spectroscopy

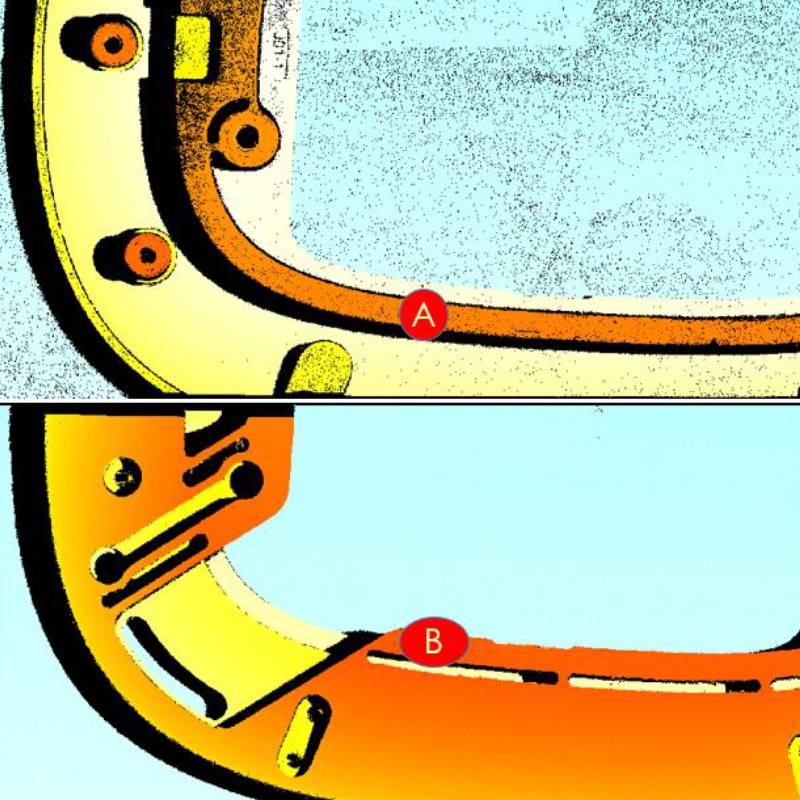

- External dimensions, height difference, contouring, gaps, cosmetic defects, etc.

- Suitable for metal parts, plastic parts and other products for headphoness

- Inspection accuracy up to ±0.005mm

- Inspection speed up to 1600PCS/H

Project Requirement

Performance Indicators

Detection Advantage

Equipment Capability

Video Presentation

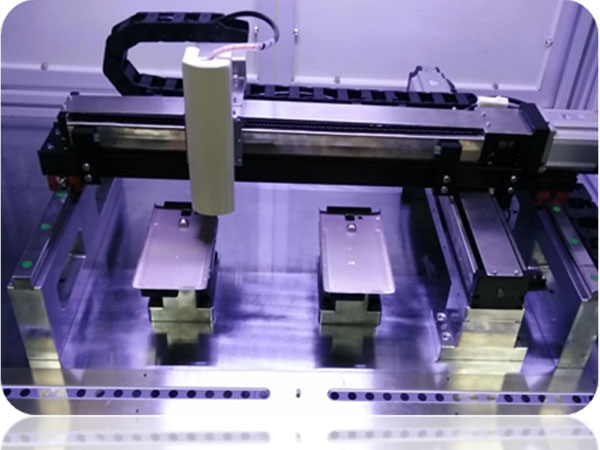

Samsun has a full set of mature and complete solutions for 3C consumer headphones products, combining vision, laser, spectroscopy and other light application technologies to meet a variety of inspection needs such as height dimension, contour, gap segment difference and appearance defects of metal and plastic parts of headphoness.

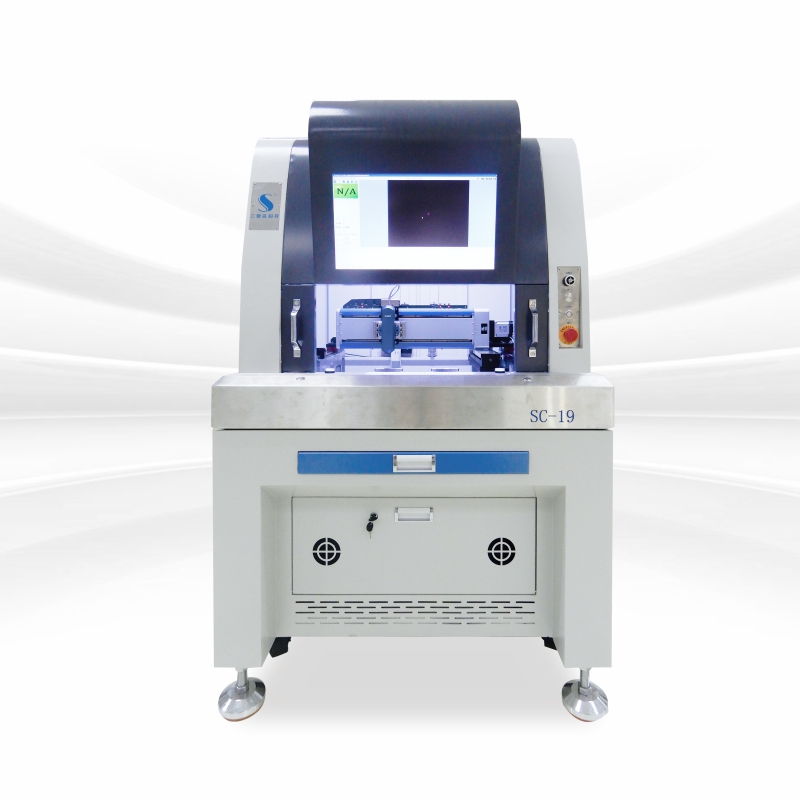

| Model | SC-190 Series | |

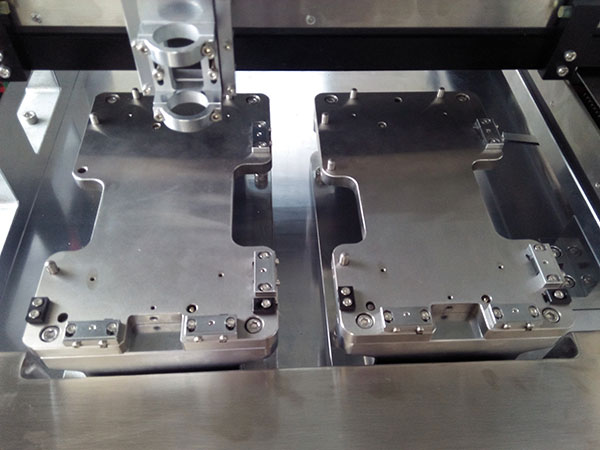

| Equipment name | Testing equipment for structural parts of headphoness | |

| Testing products | Headphoness metal parts, plastic parts, etc. | |

| Detection function | External dimensions, height section differences, contouring, gaps, cosmetic defects, etc. | |

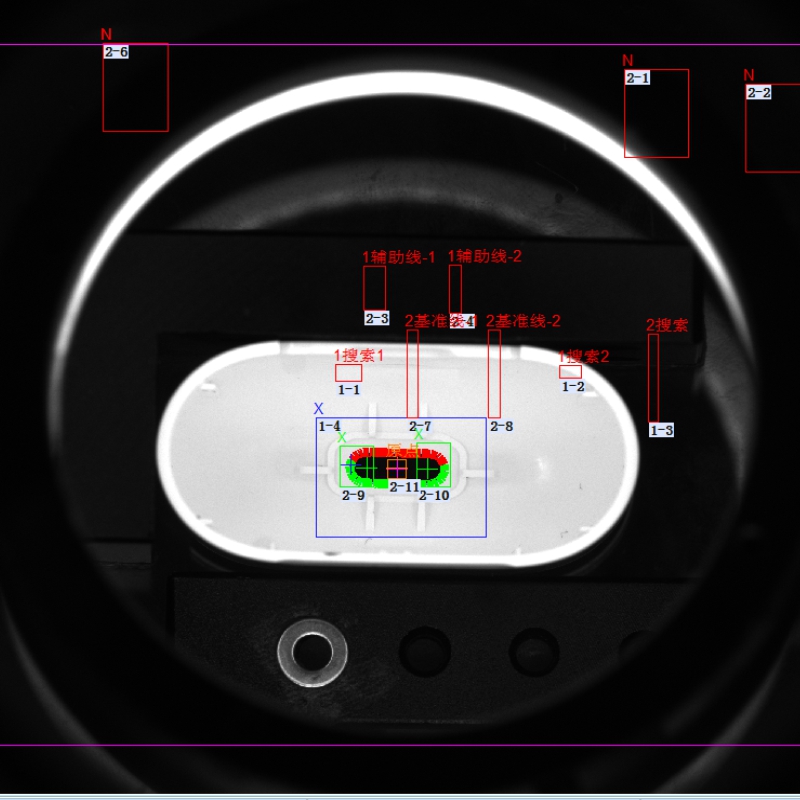

| Software | Samsun SMV vision inspection software, Samsun SLM laser inspection software | |

| Detection accuracy | ±0.005mm | |

| Testing features |

Fast measurement speed: 3~8S/PCS

Process improvement: assist in improving product yield by more than 1%

High measurement accuracy: Repeat accuracy ±0.005mm, leading in the same industry measurement, with strong versatility.

Easy to operate: automatically complete measurement and save data when placed into the product.

Convenient management: export statistical reports can be generated according to customer requirements, facilitating customer management and improving product quality.

|

|

| Production capacity | 1600PCS/H | |

| Main configuration measurement methods |

Industrial image processor: Dual core CPU, 4G RAM, 1T hard drive, 21" LCD monitor 2~5 five million industrial cameras, 1~2 line lasers Samsun vision inspection software SMV, Samsun laser inspection software SLM (online real time data collection, tolerance free setting, automatic OK/NG determination) High precision motion modules, motion servos, motors, etc.. |

|

| Loading and unloading method | Manual loading and unloading | |

| Detection method | CCD vision inspection, laser measurement | |

| Inspection stations | 2~5 CCD, 1~2 laser | |

| Dimensions (L*W*H)mm | 2000*1300*1780 | |

| Weight (kg) | 1000kg | |

| Working environment | Temperature: 20°±2° (no dew point) Humidity: 30~80% | |

| Air pressure, voltage | 0.5Mpa-0.8Mpa/220V | |