Company News

Preview︱2019 Automation South China, we look forward to meeting you

Date:2019-06-20

Source:Samsun Technology

From 26 June to 28 June 2019, the 2019 South China International Industrial Automation Exhibition will be grandly opened at Shenzhen Convention and Exhibition Center (Fuhua 3rd Road, Futian District, Shenzhen). Samson Technology, as a well-known brand and leading company at home and abroad, provides flexible and professional intelligent inspection solutions in several segments such as intelligent manufacturing, intelligent control system, machine vision, laser and confocal spectroscopy.

Industry 4.0 cannot be separated from intelligent manufacturing, and intelligent manufacturing cannot be separated from machine vision. At that time, the Equipment Division of Dongguan Samson Optoelectronics Technology Co., Ltd. will be in Hall 2, Booth 2.51 and the Measurement and Control Systems Division in Hall 4, Booth 4.91 to showcase personalised intelligent inspection solutions, which can be applied to mobiles phoness, consumer electronics, automotive industry and other intelligent inspection equipment on site.

The two divisions make their debut

Equipment Division

The Equipment Division gathers highly qualified R&D and service teams for the development, integration and project implementation of automated measurement software, and is equipped with advanced equipment such as an optical application test centre, forming the support for effective product development, production and promotion.

Equipment Division Booth: Hall 2, Booth 2.51

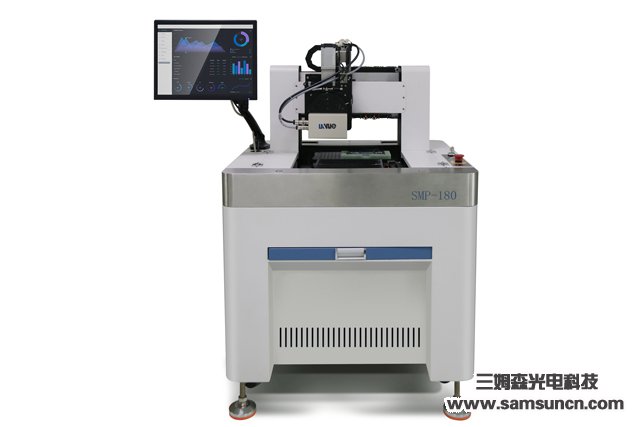

High precision 3D scanning intelligent inspection equipment

The line scan laser sensor uses a laser combined with innovative imaging algorithms to measure black or bevelled surfaces with low reflectivity and metals with high reflectivity, and to accurately capture the shape of objects with different reflectivity due to a mix of colours or materials. The SLM measurement software, developed in-house, also makes it possible to measure the shape of products flowing at high speed on ultra-fast sampling lines or devices without missing a beat, resulting in ultra-stable and highly accurate measurements. The main applications are in the inspection of contours, dimensions and segment differences of metal mobiles phones cases, cell back covers, small hardware, circuit boards and other products.

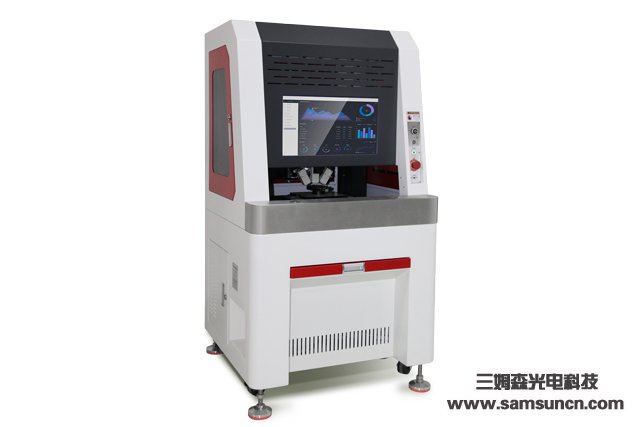

3D Glass Profile Inspection Equipment

The 3D glass contour inspection equipment is a set of inspection equipment equipped with high pixel camera, light source, lens and non-contact 3D probe and its controller, which combines vision camera and spectrum for product positioning, installation of multi-spectral probe scanning, while using EtherCAT bus control, through the PDO data synchronisation function, finally complete a set of positioning, high measurement accuracy (repeatability accuracy 0.005mm ), large detection angle, fast detection speed and wide measurement range. The main applications are 3D glass profile, roughness and shape metrology.

Material staging and testing equipment

For the measurement of segmental differences in the middle frame and back cover of mobiles phoness, the material staging and inspection equipment uses imported spectral emitters and data processing controllers to improve the detection accuracy to nano-level resolution, with a measurement accuracy of 0.008mm, and a comprehensive and accurate measurement of the segmental difference size of the product being inspected.

Measurement and Control Systems Division

The Measurement and Control Systems Division is an intelligent measurement and control solutions provider integrating R&D, design, production, sales and service. Through continuous research and exploration, Mowei has developed a number of technological innovations such as intelligent measurement and control, visual inspection system, laser inspection system, spectral confocal system, motion control system and industrial internet system, etc. The products and technologies have been widely used in the production process control system and intelligent production system in various industries.

Measurement and Control Systems Division Stand: Hall 4, Stand 4.91

Three core technologies have been developed to drive innovative and optimal intelligent measurement and control solutions, namely vision inspection systems, laser inspection systems and spectral confocal systems.

Vision inspection system demonstration platform

A machine vision inspection system is a general-purpose intelligent inspection system that usually includes five parts: camera, lens, light source, acquisition card and vision processing system. The system has high efficiency, high precision, high reliability, high flexibility, high automation, etc. It can meet the intelligent inspection needs of multi-functional multi-camera and multi-station, mainly used for all kinds of assembly positioning, quality inspection, product identification, dimensional measurement, etc.

Spectral confocal detection system demonstration platform

Spectral confocal inspection system demonstration platform

The Confocal Spectral Displacement Sensor is a high-precision displacement sensor based on the dispersive confocal principle, with a measurement accuracy of the order of nm, which can effectively measure almost all types of materials (metals, glass, ceramics, semiconductors, paper) and different surface conditions. It has been widely used for various high precision non-contact measurements of object displacement, vibration, deformation, thickness of transparent bodies, etc.

Laser inspection system demonstration platform

The laser measurement system is a multi-sensor integrated automated measurement system that uses a beam of light for measurement and has non-contact characteristics for ultra-high speed and accurate product height, distance, spacing, point to point, point to line, area and angle measurement applications.

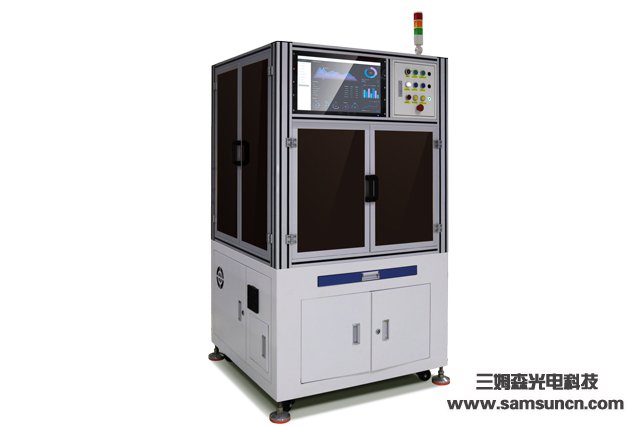

mobiles phones centre frame automatic inspection equipment

The mobiles phones centre frame automatic inspection equipment is a general-purpose intelligent inspection equipment, the equipment adopts the visual inspection software and Samson dispersion confocal spectral measurement software, mainly for mobiles phones metal centre frame, 2.5D/3D glass and other products of surface roughness, contour, scratches, blind hole inside diameter, appearance defects and other high-precision detection, even if the material of the product to be inspected is transparent objects, such as Even if the material to be inspected is transparent, e.g. film, glass, transparent adhesive, transparent liquids, etc., it is still possible to carry out stable and highly accurate inspection, as well as for multi-layer thickness measurement.

For more information about the exhibits, please visit our booth at the 2019 International Industrial Automation Exhibition in South China from 26 June to 28 June.